Bin Picking Tutorial: Setting up Photoneo Bin Picking Studio with ABB robots

Contents

1. Prerequisities

Following conditions must be met:

- (616-6) PC Interface Module available

- (672-1) Multitasking Module available

- RoboTWareOS 5.13 and higher

+

- Robot Studio Installation (v.6.04 is recommended)

2. ABB Controller setup

Following tutorial provides step by step guide how to configure your ABB IRC5 controller and install RAPID interface for Photoneo Binpicking Solution.

This tutorial was originally written for RobotWare v.6.x and higher systems, however it should also work with older versions with minor changes.

2.1 Network configuration

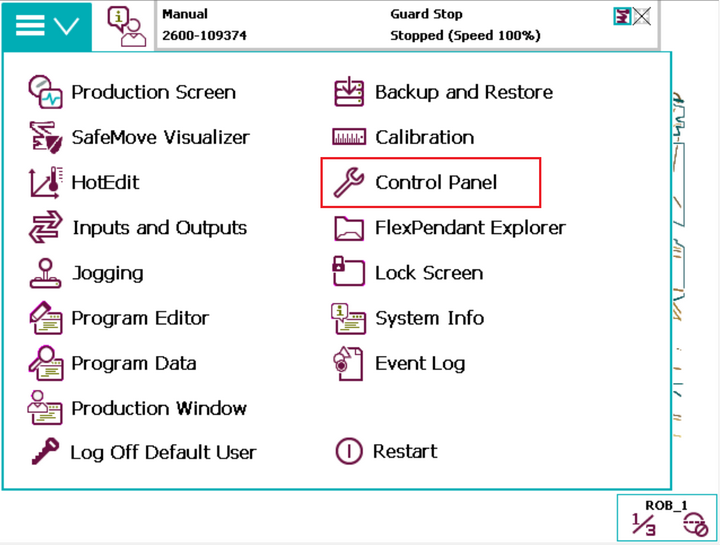

Turn on the IRC5 Controller, wait for Initialization Screen to appear, open Menu screenand select Control Panel option :

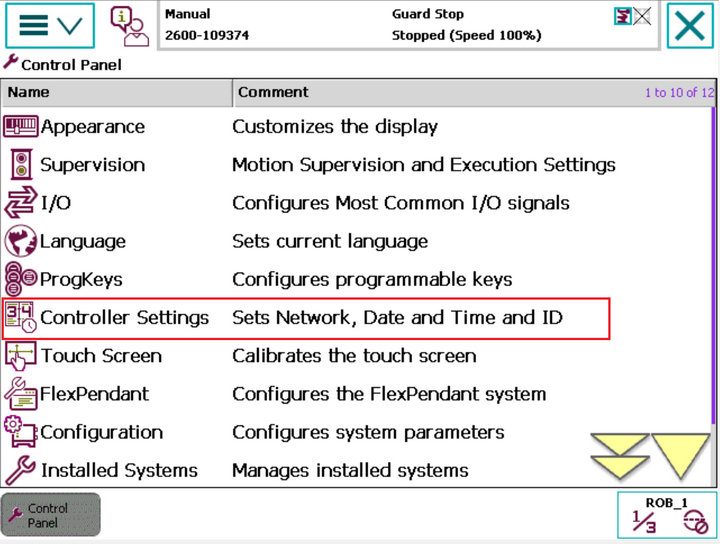

On the Control Panel pane, select Controller Settings

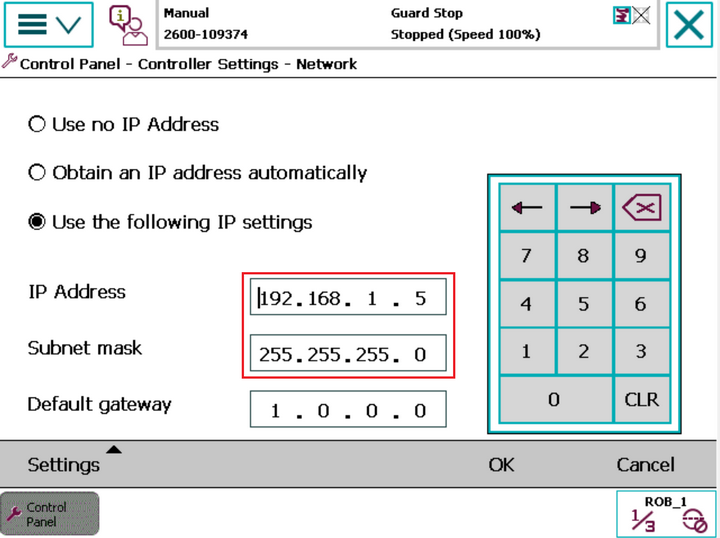

Select Settings and choose Network option

Network settings window should appear. Use the touch panel keypad to set IP address of IRC5 WAN port.

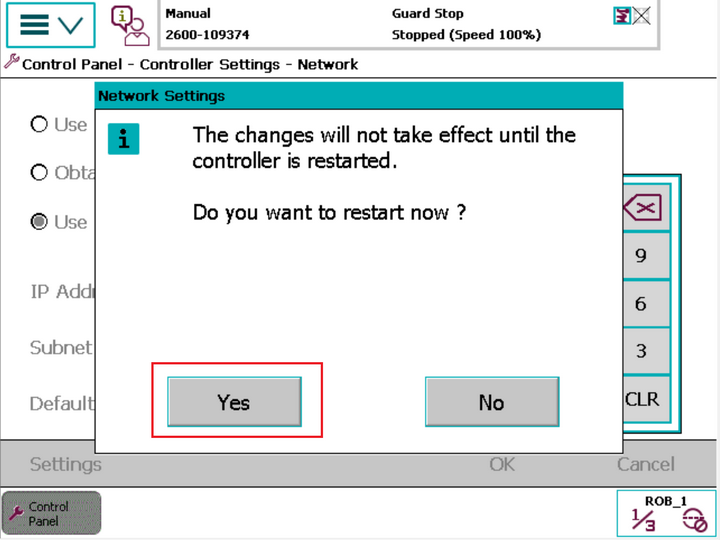

Press OK button and restart the controller to apply new settings

2.2 Use Robot Studio to Connect to IRC5 Controller

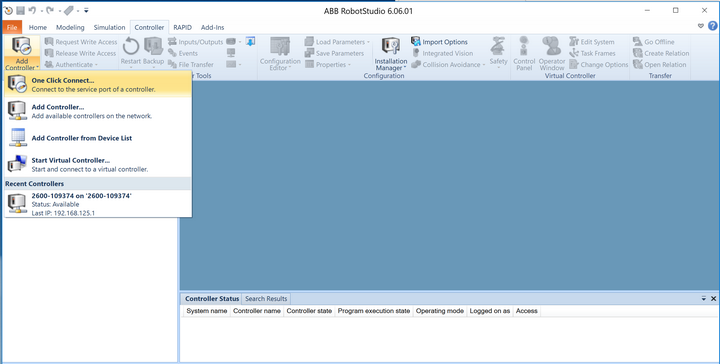

Set your local PC network settings to DHCP, plug Ethernet cable to Service Port of IRC5 Controller and launch Robot Studio.

For direct connection to Robot Controller, select Controller tab and One Click Connect option.

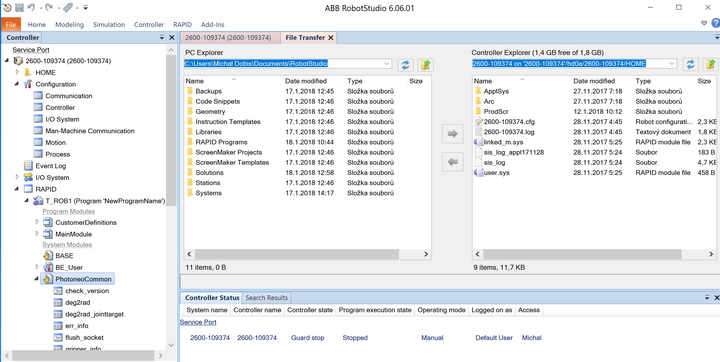

As a first step in installation Photoneo ABB Interface, you need to copy RAPID files from your PC to the Robot Controller

You can use USB stick and copy files directly from the pendant, however the most convenient way is to use Robot Studio internal File Transfer tool.

Go to Controller tab and select File Transfer tool from the menu

2.3 Configuring a I/O

2.3.1 Preparation

Assemble cables (tall box on palette with controller), specifically XP1, XP13, XP2 to the bottom side of controller, with their respective connectors on the base of robot.

2.3.2 Setting up I/O

Various links are accessible on panel inside cabinet. These signals are wired throught XS/XP13 connector underneath the cabinet, throught connection in base of robot to R1(2).CP and R1(2).CS. XT6/6.1 signals 1 to 4 are usually used to power your device (4x1mm2) with link to R1(2).CP and connectors XT5.1, XT5.2 and XT5.3 are used to provide signals for your accessories carried by robot with link to R1(2).CS.

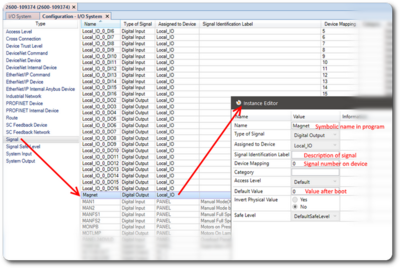

2.3.3 Accessing signals in program

Usually a I/O slave is supplied with robotic controller. If not install one inside cabinet and in Configuration - I/O System tab. Once completed a list of device’s Inputs/Outputs may appear in Signals tab. Configure them according to their specific purpose. A example of signal configuration is shown below: